A single CNC, can be the magical machine which allows us to quickly and very accurately create parts for things we are making. CNC — I a CNC machine we make parts for cars, planes and toys The machine is super cool since it can shift the way we are working and thus making our job less burdensome! Here is an interesting machine to know about and how it has helped us in our daily lives.

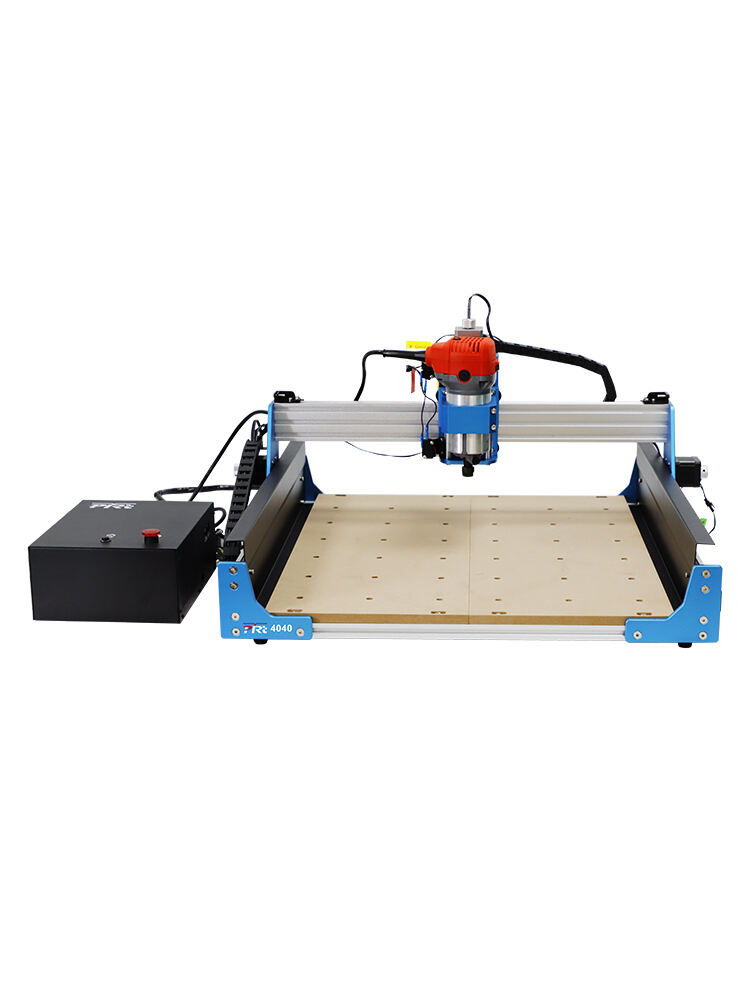

In this unit of One CNC machine is Very Big Powerfully tool which can make lots type of parts for us. To put it simply, this is a technical term that broadly describes various main components of an MRI machine, namely – computerized brain (Admin Control), its UI interface where we trained obj-file command picks and then the real time spinning part known as Spindle. The spindle spins at high speed and travels around to carve or chip metal, plastic, and other raw materials into the desired figure.

One of the explanation to this is, sometimes we use One CNC machines for such compound parts which are very difficult and not possible to make on hand. Some of the complexity in design can lead to some One CNC machines that look and work extremely well. They allow us to make things quicker and more precisely than we could ever do by ourselves. By a One CNC machines, we can manufacture one part by time, and this every time On The Money! That means our products are high-quality and everything fits together nicely.

One great aspect of One CNC-mills is that they are rich in exactness. The control panel guides the machine to show it exactly where to cut, thus there are no errors during this stage. This is perfect for making parts that require an exact fit, like gears or wheels and other mechanical pieces. This makes sure everything will integrate well without problems.

And one of the most phenomenal features about One CNC machines is that they have an extended working duration, which means it works throughout day & night without any rest! They can perform for hours or days at a time without pause! It allows us to produce many parts in very little time and may be save costs (the effect on lead times it obvious). One CNC machines work 24/7 to allow us not only avoid delaying our customers order, but also meet all the demands.

A CNC CAM be one of the most helpful tools to make our job more convenient and time effective. It can execute a big chunk of the process necessary to produce some part for us and this way, it frees our hands from carrying out that task too which also helps avoid errors. This is exactly the concept of automation: taking care by machine means we can get to handle other important stuff at that time in hand.

CNC machines also have a very wide use as one machine is used to do several varieties of work in many fields and industries, from aircraft manufacturing automobile production to medical devices. This has helped One CNC machines play a crucial role in the airplane industry, producing advanced components for engines and landing gear. This is very important as we all know air planes needs safe and sound other components on a regular basis.

PRTCNC Factory is housed in the building which is equipped with four workshops This helps make sure one cnc that is beneficial We also have a huge warehouse that is well-organized and contains five floors where we shop our large stock we're able to guarantee speedy shipping time and cut down the waiting time for the customers to have top-quality CNC machines The time to deliver regular devices is between 5 to 7 days Machines made to specific customer specifications usually just take 15-30 days

Foshan Puruite Technology Co., Ltd (PRTCNC Factory) is a prestigious ODM one cnc manufacturer with a focus on CNC routers. We've been devoted to research, development production, sale and maintenance service of high-quality CNC routers since the year 2012 when we started our business. Our self-production and self-sales model does not just guarantee the supply of superior CNC routers but also helps customers save their budget.

We're a CNC router maker with years of experience in exporting services and products and producing services which are custom meet various requirements of customers We are conscious that our clients have unique needs and could be running within a spending plan Consequently we provide methods to meet their needs Our experience allows us to create machines with exemplary appearance and performance while working within budget limits We partner with top CNC brands such as Sainsmart VEVOR and one cnc These partnerships let us improve our services and products as well as provide top CNC routers to our customers

We place a high value on scientific and one cnc quality control measures. To ensure the highest quality of our products we use our own production process which involves testing, disassembling and packing CNC router machines. We pay attention to each and every detail beginning with the selection of the raw materials to testing and production stages. In addition, we offer a comprehensive after-sales system with 24 hour, no-cost technical assistance via email, Skype, phone, and TradeMessenger.