Provided by Cerritos CollegeTable routers play a significant role in the world of woodworking and carpentry, where one needs things done with precision efficiency for professional results. It is these indispensable devices that are generally known for revolutionizing the crafts by providing a robust basis to design and execute needles sharp cardiospasm accurately. In this comprehensive table router machine buying guide, we are going to discuss how these machines can help improve workshop performance and functionality in depth so you have a clear understanding of what it does before exploring the most important factors to consider while choosing. their model suitable for your own space as well as premium features that differentiate certain tools from others; It also presents some potential design applications where they excel, along with advice on maintaining them both prolonging its life span

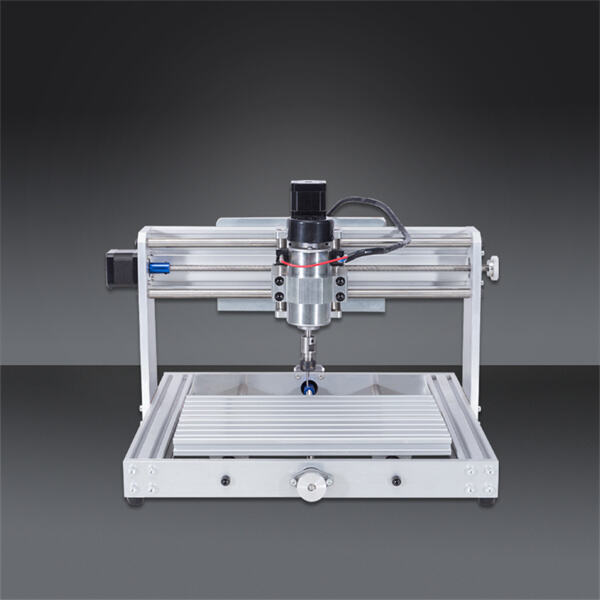

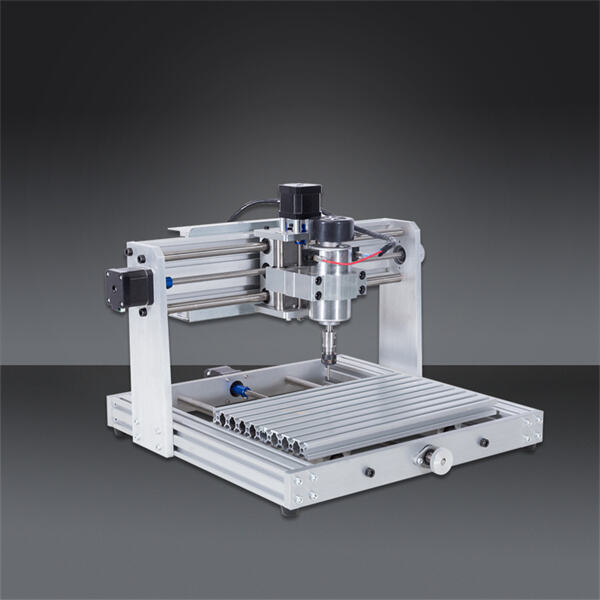

Table router machines have a unique appeal: they are meant to elevate precision and workflow efficiency in woodworking tasks. They help reduce potential errors created by vibrations that can occur during the milling or manufacturing process, through secure clamping of workpieces with a table. Fast and accurate depth-of-cut adjustments and bit changes help create a repeatable finish across multiple pieces. This fence is the guide that ensures a straight cut and aligned edge profiles with an adjustable system vertically & horizontally. Dust collection port Most models have this feature that helps keep the workspace clean and makes working easier, thereby improving routing overall.

You require the right table router machine for this purpose, in order to address all your needs accordingly as there can be several factors involved. The size of your work area and the kind of projects you normally do in it will determine which one is best for you. Benchtop models offer perfect portability and space-saving convenience for less demanding tasks or smaller work spaces. The latter, meanwhile are more specialised focussing on heavy-duty work and longer production runs. Another key for the machine is in regards to its horsepower, the working area with bigger bits and harder-to-cut materials can be handled more efficiently by higher power routers. Further, variable speed control is beneficial as it allows users to set the router's speed based on material and bit size for best cutting results.

Table Router machines are perceived as high quality devices above the rest with cutting-edge resources that give increased functionality and improved user convenience. Many of these machines feature micro-adjustment on the fence and router lift systems allowing for tiny adjustments with exactness. This is for better control and the longer life span of a motor as soft start motors reduce startup torque. With electronic feedback systems, the speed will be consistent all through cutting dense materials so you get smoother cuts! In addition, dust collection is high on premium machines and they are ergonomically desirable because controls are typically appropriate at the large front hand wheels; more similar to modern table saws.

Its ubiquitous table router machines and widespread usage in a range of design applications just go to show how indispensable these tools are for the creative freedom. With hand-placed-inlays, custom architectural moldings crafted to match existing profiles and in-house edge profile capability - From dovetail joints for strength to creating the contractor needed shapes, our tables are virtually limitless. Artisans can certainly turn their design ideas into life with a large number of sizes and shapes of available router bits. These machines allow furniture, cabinets and architectural millwork to be crafted with fine detail work as they have the capacity of cutting them accurately including rabbets, dadoes and curves. Believe it or not, jigs and templates also increase the opportunities that are available in creativity since with them; one can replicate even the most intricate of designs.

PRTCNC Factory operates from the table router machine that is home to four fully-equipped workshops ensuring production that is efficient In addition we have large and well-organized five-story warehouse to store our massive inventory this permits us to deliver quick delivery and shorten the wait time for the customers to get our top-of-the-line CNC router machines The standard distribution time for machines is generally 5-7 days while machines built to customer specifications are usually delivered within 15-30 times

Foshan Puruite Technology Co., Ltd (PRTCNC Factory) is a prestigious table router machine OEM manufacturer specializing in CNC router machines. Since the year 2012 when we started our business we have committed ourselves to the design, production and distribution of top-quality CNC routers, as well as maintenance services. Since 2012, when we first started, we have been dedicated to research, development and manufacturing of high-quality CNC router machines. We also provide maintenance services.

As a CNC that is expert router manufacturer We have extensive expertise in exporting products and service customization to meet up with the diverse needs of our customers Our company is conscious which our clients have unique requirements and may have budget that is tight So you can expect solutions to meet those needs The ability is had by us to develop equipment that is both breathtaking and perform well but still within budgetary constraints We collaborate with a few of the most notable CNC brands such as for instance Sainsmart VEVOR and Yorahome These table router machine allow us to enhance our services and to present CNC that is superior router for the consumers

We follow strict and controlled quality assurance procedures. To ensure the best quality of our products we use a unique production process which involves testing, disassembling and storing CNC routers. From the selection of raw materials to the stages of production and testing We pay close attention to every detail. We also offer a comprehensive after-sales support system, which includes technical assistance 24 hours a day via Skype, table router machine, email and phone.

Your table router machine needs to be properly maintained and taken care of in order for it to work its best as time passes. Regular dusting keeps sawdust and debris from collecting within the machine which causes moving parts to weaken. To keep your body in a good running condition, follow the manufacturer's guidelines to lubricate moving parts of machines. Using sharp bits without nicks will make clean cuts and prolong the life of the motor. Belt, Cable and Electrical Connections Regular checks on belts, cables and electrical connections can help to identify any problems before they become apparent. Lastly, ensuring to store your machine in a dry and dust free environment when not being used greatly extends the life of you equipment.

To sum up, the table router machines make woodworking more accessible for everyone with their combination of precision engineering and versatile functionality. Choose a suitable machine, get comfortable with and utilize the features of premium models available like computerization etc., familiarize yourself with applications in design and dedicate time to its proper maintenance woodworkers are able realize this powerful tool's full potential-transforming ideas into reality that stand the test of time.