Eh bien, aujourd'hui nous allons vous parler de cette chose spéciale qui aide à fabriquer des meubles et des sculptures magnifiques OU PEUT-ÊTRE UN PEU DE MAGIE avec du bois travaillé par des menuisiers du monde entier. Les menuisiers peuvent l'utiliser pour façonner et sculpter des matériaux en bois avec une grande précision afin qu'ils apparaissent toujours comme le menuisier le souhaite. Ce texte va vous apprendre que les machines CNC pour le bois font le travail, économisant du temps et de l'argent à nos menuisiers, transformant progressivement le secteur de l'industrie du bois. Le travail du bois avec ou sans machines CNC : ce qui est excitant a grandi dans l'industrie Atari du mobilier : le chemin vers la fabrication d'une machine qui travaille plus avec la technologie sur les bois.

Dans le monde de l'usinage CNC en menuiserie, cela signifie que les deux sont toujours l'un contre l'autre lorsqu'il est question de faire des choses parfaitement carrées. Ses pièces seront usinées sur une machine CNC très délicatement — par exemple, du bois pour des avions miniatures. C'est pourquoi, lorsque menuisier fabrique plus d'une chaise, chacune ressemble exactement à l'autre sous tous les aspects et s'assemble parfaitement avec sa jumelle. Cela peut être utilisé par les menuisiers pour la fabrication de conceptions fantastiques et très précises sur les meubles, ce qui serait presque impossible à construire manuellement. Ils ont pu créer des motifs et des formes encore plus complexes qui prendraient beaucoup de temps à sculpter ou découper manuellement. La technologie CNC en menuiserie permet aux artisans de découper des motifs complexes qui sont irréalistes à créer à la main. Et ainsi, ils passent plus de temps à être créatifs et à imaginer de nouvelles idées, plutôt qu'à couper du métal toute la journée.

Cela est également bénéfique pour les menuisiers car le travail du bois par CNC peut être rapide et économise une bonne somme d'argent. Un CNC peut reproduire un design avec pratiquement 100 % d'exactitude dès que le premier composant est créé. Autrement dit, un opérateur peut produire des centaines de chaises ou un autre type de produit en bois en peu de temps et sans travail supplémentaire. S'ils ont un fichier pour reproduire la même table – des centaines de fois, une machine CNC peut réappliquer ce design sur un nouveau matériau et l'exécuter successivement sans redémarrer à chaque tâche. De plus, l'usinage du bois par CNC réduira vos déchets et vous fera gagner beaucoup de temps. On utilisera bien sûr tous les tas de bois avec cette machine, aucun ne sera gaspillé. Cela ne permet pas seulement d'économiser de l'argent au menuisier, mais c'est aussi écologique car moins d'arbres sont abattus et gaspillés.

Beaucoup de choses ont changé avec l'introduction de l'usinage CNC dans le travail du bois. Cela permet aux menuisiers de créer des formes et des produits incroyables qui n'étaient pas possibles jusqu'à présent. Créer un design à la main prendrait des heures pour passer par toutes ces couches complexes. Avec l'usinage CNC, les menuisiers peuvent désormais réaliser des conceptions encore plus élaborées à un niveau de production proche ou meilleur qu'auparavant, sans avoir besoin des compétences de finition réservées uniquement aux meilleurs entrepreneurs. Un aspect le plus important de cette technologie est sa capacité à produire davantage avec moins de ressources, afin qu'elle soit accessible au plus grand nombre d'utilisateurs possible. Ce qu'elle fait, c'est qu'elle vous permet de créer des meubles aux normes industrielles pour une fraction des coûts — même si c'est juste vous et votre petite entreprise.

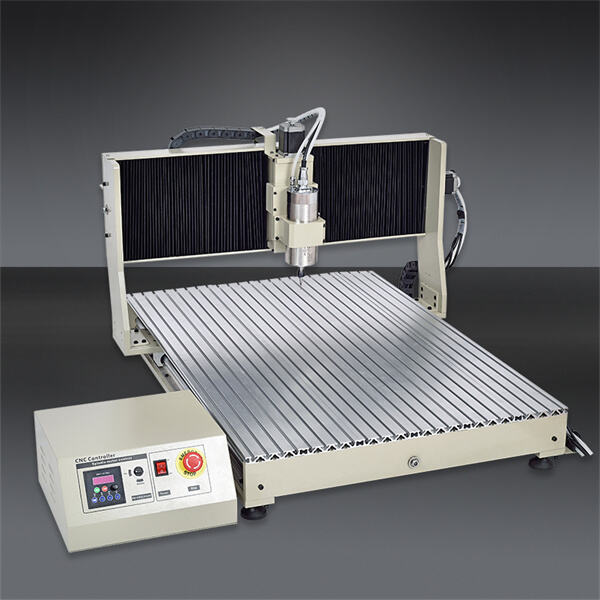

L'usinage CNC est un découpage de bois par CNC (avec fraisage). La simple lame rotative / coupeur de bois permet de couper le bois en forme parfaite. C'est principalement la cause de cette augmentation sans précédent de l'usinage CNC, car il permet aux menuisiers de créer des conceptions complexes très riches. Les sculptures les plus détaillées ou les pièces aux formes étranges peuvent être réalisées sans passer des dizaines d'heures à sculpter à la main. L'usinage CNC est le procédé idéal pour fabriquer des meubles haute précision, des sculptures complexes ou tout type de petit objet en bois de qualité.

Comment un CNC pour le travail du bois peut-il espérer faire de bonnes choses ? De nombreuses sculptures ou autres œuvres artistiques qui seraient sinon presque impossibles pour un humain à produire deviennent relativement triviales lorsqu'elles sont fabriquées à l'aide d'outils assistés par ordinateur comme les machines CNC. Ou encore, les artistes peuvent être moins limités par leur travail et pousser plus loin les limites, créant quelque chose de plus complexe, mais aussi peut-être en termes d'originalité. De plus, une machine CNC pour le travail du bois est aujourd'hui un équipement merveilleux qui permettrait aux propriétaires et aux amateurs de fabriquer des pièces uniques de mobilier domestique. En effet, chacun a un goût et des besoins différents en termes de design ; ainsi, grâce à la technologie CNC, les menuisiers peuvent produire n'importe quel type de meuble selon la référence de leurs clients. Fondamentalement, chaque pièce de bijouterie est unique et peut être personnalisée spécialement pour eux.

PRTCNC Factory propose des machines-outils CNC pour le travail du bois depuis une installation abritant quatre ateliers entièrement équipés, garantissant une production efficace. Nous disposons également d'un vaste entrepôt bien organisé sur cinq étages pour stocker notre large inventaire, ce qui nous permet de garantir des livraisons rapides et de réduire la durée d'attente pour nos clients afin qu'ils reçoivent des machines CNC de haute qualité. Le délai de livraison standard pour les appareils est généralement de 7 jours, tandis que ceux fabriqués selon les spécifications des clients sont généralement livrés en 15 à 30 jours ouvrables.

Foshan woodworking cnc Technology Co., Ltd. (PRTCNC Factory), un fabricant renommé en tant que sous-traitant ODM OEM de machines d'usinage CNC, est une entreprise bien connue dans le domaine de la fabrication sur mesure. Depuis 2012, date de notre création, nous nous engageons dans le développement, la recherche, la production, la vente et l'entretien de machines d'usinage CNC de haute qualité. Notre modèle de production et de vente interne garantit non seulement la disponibilité de fraiseuses CNC de qualité supérieure, mais permet également aux clients d'économiser leurs fonds.

En tant que fabricant de machines routeuses CNC pour la menuiserie, nous avons maintenant une grande expertise en matière d'exportation de produits et de personnalisation des solutions pour répondre aux besoins variés des clients. Nous comprenons que nos clients sont uniques et peuvent travailler dans un budget. Nous offrons donc des solutions pour répondre à ces exigences. Notre expertise nous permet de créer des appareils avec un excellent design et des performances, tout en restant dans les contraintes budgétaires. Nous collaborons avec des marques CNC renommées telles que Sainsmart, VEVOR et Yorahome. Ces partenariats nous permettent d'améliorer nos produits et d'offrir les meilleurs routeurs CNC à nos clients.

Nous attachons une grande importance aux mesures de contrôle qualité scientifiques et rigoureuses pour le contrôle qualité. Pour garantir la plus haute qualité de nos produits, nous utilisons une méthode de production exclusive qui implique des tests, la décomposition et le stockage des fraiseuses CNC. Nous portons une attention minutieuse à chaque détail pris en compte, de la sélection du matériau brut aux phases de test et de production. De plus, nous disposons d'un système complet de support après-vente qui offre un soutien technique gratuit pour les fraiseuses CNC par e-mail, Skype, téléphone et TradeMessenger.