CNC carving is a pretty awesome tech that allows us to transforming ideas into real stuffs. CNC: Computer Numeric Control. Despite that its concept may sound pretty revolutionary: in this scenario, we employ computers to foster ordering machines for engraving shapes and designs onto diverse materials such as wood, metal or plastic. It is unbelievable that these machines are able to take our ideas and breathe life into them!

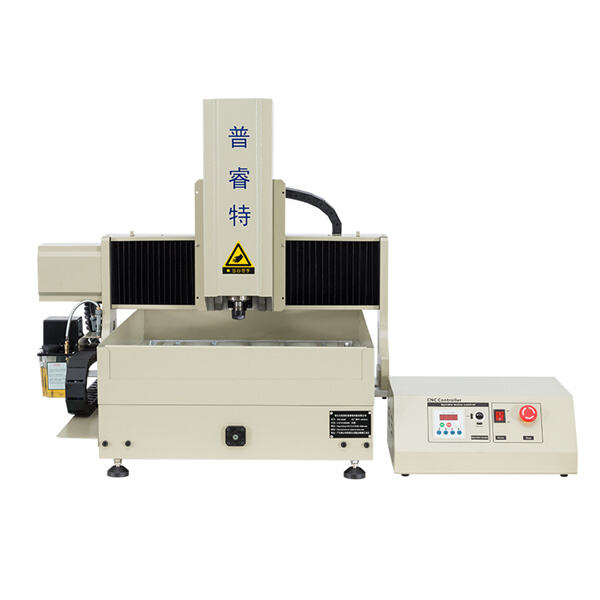

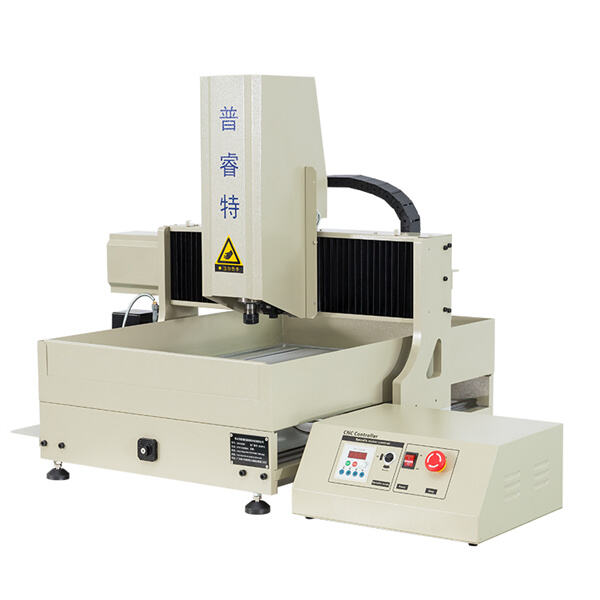

CNC is helpful in engraving because you can use it to make an accurate and detailed design. This enables us to create representations that virtually match what we imagine. So it is a great resource to make gifts or decorations, and even elements for machines that assist in other tasks. A CNC carving machine comes with numerous essential parts, including the spindle, the motor and the controller. All of these parts have a purpose to perform, and they help each other out in shaping the final product we want.

Turning a hollowed block of wood into an intact object like this is nearly magical, and the CNC technology definitely feels akin to wizardry! It will take our thoughts and make them issues. In order to do any of that, however, we have opened a special piece of software in our computer where we can make the design behind what will be carved. This software is CAD, that stands for Computer-Aided Design. It is what allows us to design on the screen. After we get our design, this accepts commands from the software about how to carve. They determine how quick to move, which way to travel and low deep below the surface of a piece work you are cutting. CNC carving — Produces a very accurate design that you can repeat over and again error free.

These Carving CNC Machines are redefining the way of things making. Until then, such machines made it more challenging to devise intricate plots. Today however, they allow to get plain materials like a wood block or metal sheet and carve them into one of the kind shapes with awesome designs. Everything from a simple wooden sign that says “Welcome” 7′ long to parts used in large machines. Projects like this are the reason that CNC carving exists! Where everybody is trying out their hand noobs and weavers, craftsmen approach CNC Carving because it offers a ton of excitingly creative opportunities.

CNC carving has gained immense popularity in the recent past, and as a result many are enjoying it today for pure fun. So, if you consider cheaper CNC carving and want to move on a creative path then here is a small guide for beginners who are going to use it.

Draw your design. And CAD software for totally creating your design from scratch. Or look for them online and adjust the ones you like to suit your ideas. It's a very inspiring thing to see!

Load your program. Once that is all done, you are ready to upload your design into the software of the machine. It does the rest for you. Note: Because carving on CNC takes time and patience, waiting for a bit of your work.

We're a cnc carving manufacturer with extensive expertise in exporting products also as tailoring services to meet a number of customer requirements We realize which our customers might have particular needs or work inside a budget that is tight and our company is dedicated to delivering solutions that match the needs of their customers Our expertise lets us produce machines with exceptional look and performance while working within budget constraints We partner with top CNC brands such as for instance Sainsmart VEVOR and Yorahome These partnerships help us to enhance our services and also to provide CNC that is superior router for our consumers

Foshan Puruite Technology Co., Ltd (PRTCNC Factory) is a prestigious cnc carving OEM manufacturer specializing in CNC router machines. Since the year 2012 when we started our business we have committed ourselves to the design, production and distribution of top-quality CNC routers, as well as maintenance services. Since 2012, when we first started, we have been dedicated to research, development and manufacturing of high-quality CNC router machines. We also provide maintenance services.

We are committed to scientific and stringent quality control measures. Our cnc carving production process involves the installation, testing and then disassembling and packaging the CNC routers for a high-quality product. From the selection of raw materials to the testing and production phases, we maintain meticulous attention to detail. Additionally, we have a comprehensive after-sales system which provides 24/7, free technical assistance via email, Skype telephone, or TradeMessenger.

PRTCNC Factory cnc carving from a facility that houses four fully-equipped workshops which guarantees production that is efficient also we've a vast well-organized warehouse with five floors to store our vast inventory we're able to guarantee speedy delivery and shorten the waiting duration for our clients to get high-quality CNC machines The standard delivery time for devices is typically 7 days while those built based on the specifications of clients are usually delivered in 15-30 business days