Custom machining is a specific service of shaping and manufacturing metallic components. The structures are made up of gears, screws, bolts which play an important role. These parts can be found in a lot of machines we see and use everyday such cars, airplanes and also toys! Custom machining is not a simple process of making parts, it involves much knowledge and experience. Custom machining is the practice of creating components according to their order and per a customer. It is very imperative for diverse sectors concerning space (relates to airplanes), automobile, and medical instruments (machinery that are used in hospitals).

Custom machining is not for everyone, as it takes years of experience and lots of concentration. It is a deliberate process that uses precision cutting and shaping of metallic parts. As an example, if a component is not made correctly it could fail within the machine resulting in major problems. This is why the viability of custom machining depends on doing its parts properly. Some even think of custom machining as an art since it takes some skill and imagination to build parts that can be assembled flawlessly.

Custom machining is also beneficial for a wide variety of industries. These services offer different solutions that cater to particular uses of a number of companies. For example, air plane making companies use custom machining for manufacturing flying machine parts. If we take a heavy plane at first, it needs to withstand the pressure difference or so as not to break up in the air. And likewise, manufacturers of medical devices rely on custom machining to fabricate parts that are both exact fit as well. These components are usually used in aids for doctors and nurses to take care of patients, so they need precision machining. Custom machining also used for parts that require the structural integrity to be reliable, as car makers entail it in manufacturing. This is to ensure the safety of drivers and passengers.

Custom CNC machining is a popular form of custom manufacturing. CNC : Computer Numerical Control. That is to say, these go by managed through computers and they generate very accurate specified components. CNC MACHINING : CNC machines are extremely accurate as well fast at manufacturing complex parts. A good example of this is if a company needs many parts to be built within a short period, then CNC machining would work best. Many industries prefer custom CNC machining for the fast, efficient and more consistent end product delivered.

Consider Some Custom Machining to Make Your Parts the Best They Can Be Parts that are designed with a custom machining solution is almost always better than parts made another way. This is because they tend to be triter and hence, more snug-fitting. They are also the strongest, so they can handle a lot of stress and pressure. The truth is, however, that they are often significantly more durable and able to operate longer without the need for replacement. Which is why most of the businesses opt for custom machined parts. Well, there you go apart from all else if your work requires parts these custom machining services will be pretty helpful for the best results.

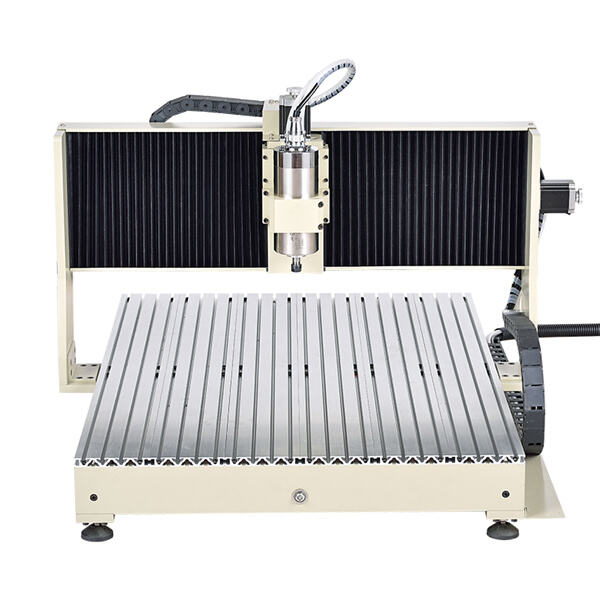

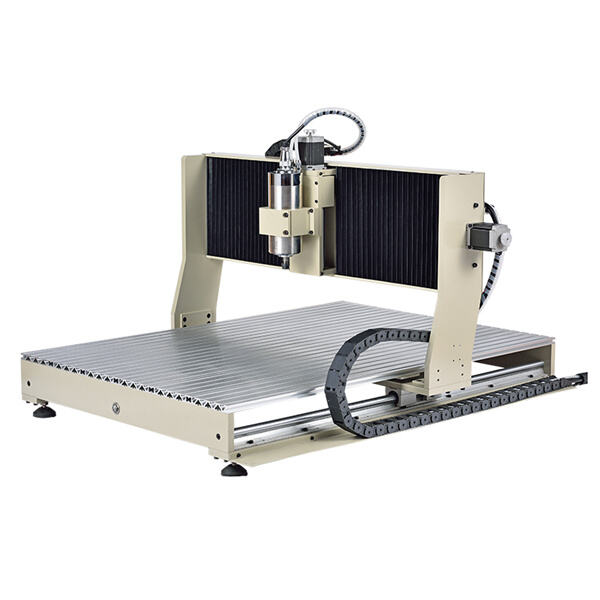

We place a high value on scientific and custom machining quality control measures. To ensure the highest quality of our products we use our own production process which involves testing, disassembling and packing CNC router machines. We pay attention to each and every detail beginning with the selection of the raw materials to testing and production stages. In addition, we offer a comprehensive after-sales system with 24 hour, no-cost technical assistance via email, Skype, phone, and TradeMessenger.

Foshan custom machining Technology Co., Ltd. (PRTCNC Factory) an acclaimed ODM OEM manufacturer of CNC router machines is a well-known ODM and OEM company. We've been committed to development, research, production, sale, and maintenance of top-quality CNC router machines since the year 2012 when we started our business. Our self-production and self-sales model will not only guarantee the availability of superior CNC routers, but also allows customers to save their funds.

We're a CNC router maker with years of experience in exporting services and products and producing services which are custom meet various requirements of customers We are conscious that our clients have unique needs and could be running within a spending plan Consequently we provide methods to meet their needs Our experience allows us to create machines with exemplary appearance and performance while working within budget limits We partner with top CNC brands such as Sainsmart VEVOR and custom machining These partnerships let us improve our services and products as well as provide top CNC routers to our customers

custom machining runs from a center that houses four completely equipped workshops ensuring production that is efficient We also have a huge well-organized warehouse with five floors where we store our large stock we're able to make sure speedy delivery and shorten the waiting time for our customers to receive top-quality CNC machines The standard distribution time for machines is usually 7 times Machines built in line with the specifications of the consumer are typically delivered in 15-30 days